Comprehensive Otolaryngology

(384) Point of Care 3D Printing of Tracheostomy Tubes

Monday, October 2, 2023

2:45 PM - 3:45 PM East Coast USA Time

Has Audio

Mikayla Huestis, MD

Otolaryngology Resident

Eastern Virginia Medical School

Norfolk, Virginia, United States- BS

Barry Strasnick, MD

Department Chairman

Eastern Virginia Medical School

Norfolk, Virginia, United States

Presenting Author(s)

Senior Author(s)

Disclosure(s):

Mikayla Huestis, MD: No relevant relationships to disclose.

Barry Strasnick, MD: No relevant relationships to disclose.

Introduction: Tracheostomy is a common otolaryngology procedure and there are a variety of standard tracheostomy tubes available. For some patients the available tracheostomy tubes do not ideally fit due to obesity or anatomical variations. Previous research has shown custom tracheostomy tubes can be designed and successfully printed with PLA, however this has not yet been done at the point of care.

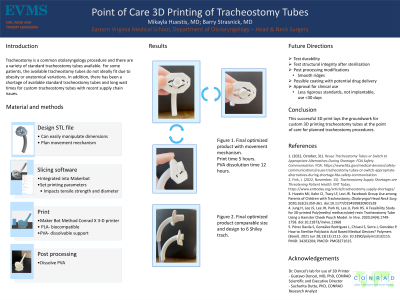

Methods: We designed a STL file with customizable lengths roughly based on the dimensions of commonly used 6 Shiley trach. We used a Maker Bot printer using PLA and PVA as dissolvable support material to print the model.

Results: We successfully printed tracheostomy tubes at multiple lengths resembling standard tracheostomy tubes. The print time was 3 hours, 5 hours with the baseplate, and PVA dissolution time 12 hours.

Conclusions: This successful 3D print lays the groundwork for custom 3D printing tracheostomy tubes at the point of care for planned tracheostomy procedures.